Asset Management

With vast low-cost storage area, ready-built warehouse and deep-water heavy-duty jetty, Singatac is your ideal partner whom can provide a ‘single-stop’ solution to companies that require a quick turnaround of vessel operations, open yard support services and end-to-end logistics solutions.

Rig lay-up and preservation services are tailored to our clients’ requirements to prevent excessive or accelerated deterioration of the rig and its equipment. These preservation procedures will greatly depend on a company’s needs to either warm stack or cold stack their assets.

– Pre-Stacking Survey for preservation stacking planning

– Warm Stacking (contract ready)

– Cold Stacking (dead vessel)

– Preservative Measures

– Maintenance

– Re-commissioning and Reactivation

The objectives of the Singatac asset preservation program are twofold and are noted in no priority, one to minimize the company’s exposure financially while new revenue streams are being sourced. While at the same time protecting the assets ensuring the equipment’s full term “life cycle” can still be realized, and as a consequence the unit and assets returned to service economically in the shortest possible period of time. Our competitors are focused in the main on preservation only; our first hand operational experience uniquely aligns us with our clients’ requirements.

Classification Societies require differing levels of SPS Surveys to be conducted every 3, 5, 10 and 15 years. This involves detailed structural investigation and various inspections to ensure structural watertight integrity.

During the Special Periodical Survey many companies take the opportunity to plan and conduct upgrades and maintenance to major equipment during this downtime period. Singatac can greatly lighten the burden for clients by either managing or assist with these projects.

Our in-house expertise, experience and tools support a safe, reliable and certified receiving and disposal centre.

Our engineers, environmental, cost-estimating and risk management professionals are adept at successfully managing complex and challenging decommissioning projects.

Working as a trusted partner, we add value to projects through our adaptability as decommissioning plans can change and the pace of the project sometimes needs to adjust due to external factors. We collaborate closely with clients, focusing on their goals to determine the most robust solution in terms of safety, the environment and the community, while not losing sight of the need to manage and reduce costs.

Sapura Kencana Australia Pty Ltd (Sapura Energy) would like to recognize the excellent result produced by Singatac Engineering Pte Ltd in the safe and efficient removal & disposal of the Quadrant EAST SPAR Navigation, Communication and Control Buoy. The project included the removal of hazardous materials and the sequential dismantling of the structures.

Danny Ma, Project Manager

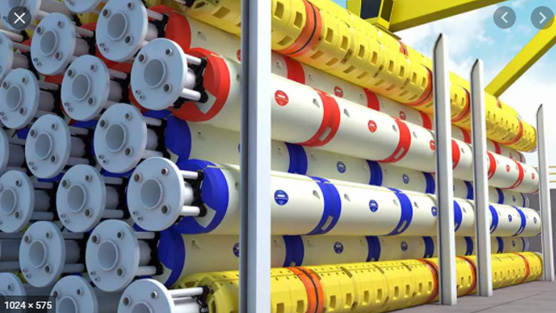

Singatac provide vast and low-cost storage area for general oilfield equipment, tubular products such as drill pipes, drill collars, tubings, casings, conductor pipes, and other offshore production equipment.